- Bhosari, Pune, Maharashtra

- GST NO. : 27AUXPS9759F1ZF

- View Mobile Number

| Business Type | Manufacturer, Supplier |

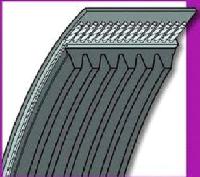

| Material | Rubber |

| Condition | New |

| Application | Moving Goods |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

K-1 = Kevlar construction. A proven performer in both glass and aluminum extrusion. Good abrasion, cut and heat resistance, make K-1 the belt of choice for ribbon lines, Lehr loaders and TV funnel transfers. Belts are made endless for run out and transfer in aluminum extrusion process.

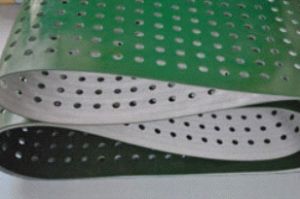

K-2 = Smooth weave, suitable for light weight hot end process. May be used for breakaway lines in windshield manufacturing. Belts are cleated for use on flare machines. Treated belt may be used for scoop liners.

K-2/K-4 = Woven Kevlar designs offer good cut and heat resistance. Used in bulb manufacturing, light casting conveying, annealing units for blow molded plastics and aluminum extrusion. K -4 has pan fibers which improve heat dissipation to extend wear and resistance to open flame.

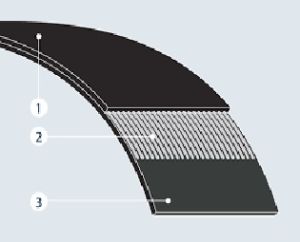

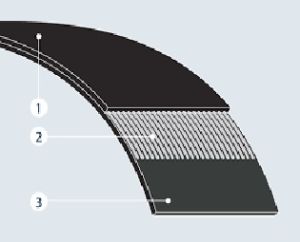

K-5/K-6 = High Temp Needled Kevlar reinforced with a thick polyester or Kevlar scrim in the middle or in the bottom. It can be laced or make truly endless (seamless). Used for conveying extruded aluminum. It can be treated with resin or PBO to provide a better resistance to extreme heat.

KEVLAR Tubes = High Temp Needled Kevlar roller. Use in aluminum extrusion process. Can be treated with resin or PBO for its use conveying the extruded billets at the exit of the press. Good resistance to extreme heat.

KEVLAR Tubes = High Temp Needled Kevlar roller. Use in aluminum extrusion process. Can be treated with resin or PBO for its use conveying the extruded billets at the exit of the press. Good resistance to extreme heat.

Special features:

Very High temperature Application up to 450˚C

Dimensions as per international standards.

JOINTS: Overlap joint.

Application Area:

Aluminum Industries

High Temperature application

Battery industries

Machine tool Industries.